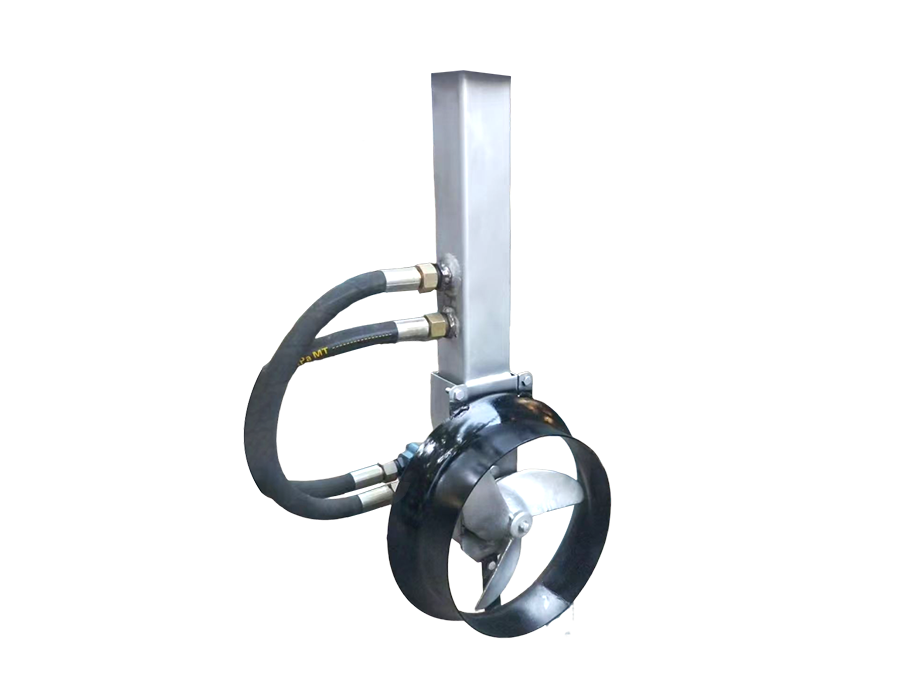

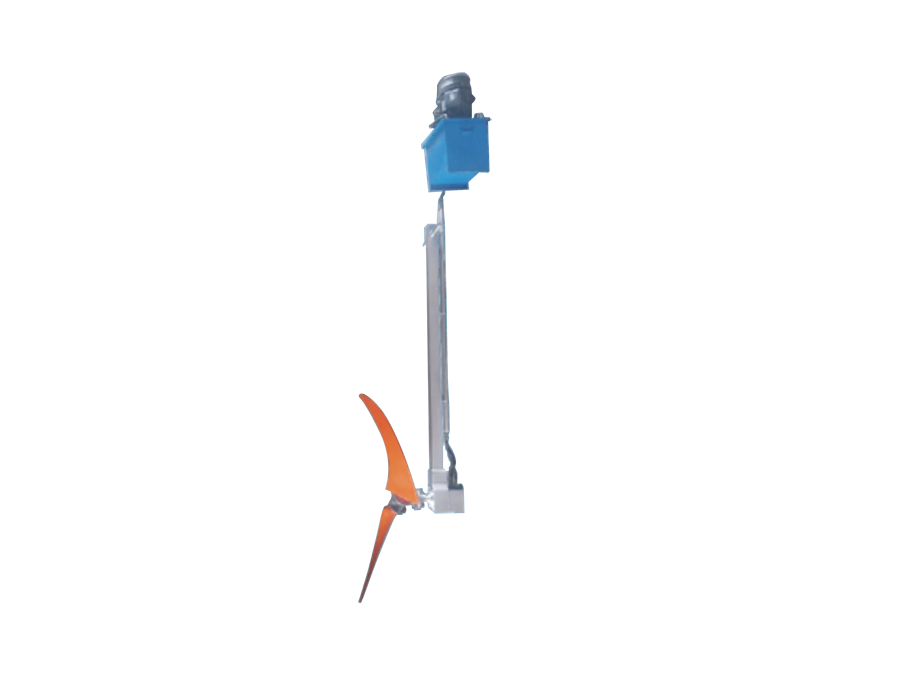

Suspended Hydraulic Drive Propeller

- Commodity name: Suspended Hydraulic Drive Propeller

Product Details

Especially recommended patented products Patent No: 201920531795.7

●The entire system has no mechanical transmission components, resulting in an extremely low failure rate and a long service life.

● Suspended installation does not require drainage or cleaning of the pool.

● Lightweight adjustable speed (thrust) to meet process requirements in energy-saving mode.

● Uses imported shaft sealing components with automatic wear compensation function.

● Especially suitable for complex working conditions such as Shenchi (tank) bodies and explosion-proof occasions.

● Internal gear oil pump, low noise, high efficiency.

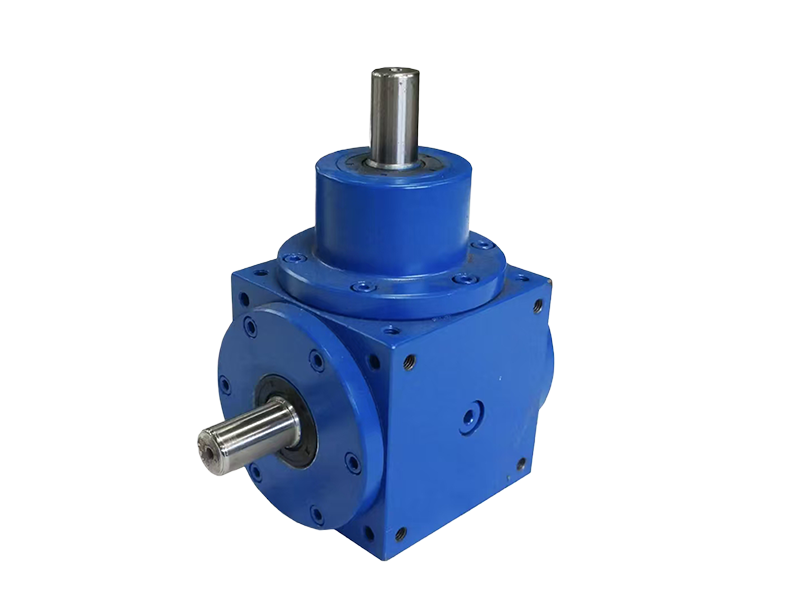

Advantages and disadvantages of hydraulic transmission

1. Main advantages

● Since hydraulic transmission is connected by oil pipes, the transmission mechanism can be easily arranged using the oil pipe connection, for example, replacing long shafts to extract oil from underground pumps, or working in containers containing explosive gases, where the power (motor, etc.) can be placed on the ground or in a safe position. Underwater machinery widely used in sewage treatment plants can place the working part underwater while the power part is above the water surface to reduce failure rates and facilitate maintenance.

● The hydraulic transmission device has a compact structure and is lightweight; a hydraulic motor of the same power has a volume only 12%-13% of that of an electric motor.

● Continuously variable speed can be achieved over a wide range through valve adjustment, and speed can be adjusted during equipment operation.

● Smooth transmission with high torque. Hydraulic transmission does not have the issue of localized stress on gear surfaces found in gear transmission, thus allowing the same shaft to transmit greater torque.

● Easy to achieve automation, with automatic speed adjustment controlled through valves.

2. Disadvantages of hydraulic transmission

● Factors such as oil leakage in hydraulic systems prevent hydraulic transmission from ensuring the accuracy of the transmission ratio, making it less suitable for precision transmission compared to mechanical transmission.

● Hydraulic transmission is sensitive to oil temperature changes; it is not suitable for situations with large temperature variations, and the normal operating oil temperature should not exceed 80°C.

● Hydraulic components require high processing precision, and excessive wear of hydraulic components is difficult to repair, generally requiring replacement.

Hydraulic series flow propeller selection reference

Specification | Pump power | Rated current | Impeller diameter | Speed | Maximum water thrust |

YXJB2.2/1100-65P | 2.2 | 4.3 | 1100 | 30-70 | 1210 |

YXJB2.2/1500-35P | 2.2 | 4.3 | 1500 | 20-35 | 1210 |

YXJB3.0/1500-42P | 3.0 | 5.8 | 1500 | 20-42 | 1600 |

YXJB4.0/1500-56P | 4.0 | 7.5 | 1500 | 20-56 | 2075 |

YXJB5.5/1800-60P | 5.5 | 11.0 | 1800 | 25-60 | 3040 |

YXJB5.5/2200-45P | 5.5 | 11.0 | 2200 | 25-45 | 3040 |

YXJB7.5/2200-56P | 7.5 | 15.0 | 2200 | 25-56 | 3550 |

YXJB7.5/2500-45P | 7.5 | 15.0 | 2500 | 25-45 | 3550 |

Hydraulic series high-speed mixer selection reference

Specification | Pump power | Rated current | Impeller diameter | Impeller speed | Installation system |

YXJB1.5/260-980 | 1.5 | 3.1 | 260 | 400-980 | Suspended installation |

YXJB2.2/320-740 | 2.2 | 4.3 | 320 | 400-740 | Suspended installation |

YXJB3.0/400-740 | 3.0 | 5.8 | 400 | 400-740 | Suspended installation |

YXJB4.0/320-960 | 4.0 | 7.5 | 320 | 400-960 | Suspended installation |

YXJB5.5/500-520 | 5.5 | 11.0 | 500 | 300-520 | Suspended installation |

YXJB5.5/620-450 | 5.5 | 11.0 | 620 | 300-450 | Suspended installation |

YXJB7.5/620-560 | 7.5 | 15.0 | 620 | 300-560 | Suspended installation |

Precautions

● During operation, the flow valve can be adjusted to change the speed (thrust), with the maximum load not exceeding the rated current of the motor.

● Recommended oil: anti-wear hydraulic oil, viscosity 37-73CS+, oil cleanliness ISO18/13 (all these pumps are equipped with filtering devices). Maximum oil temperature 80°C.

● Maximum oil temperature 80°C.

● The system should have a break-in period before operating at full load, recommended to break in for 1 hour at 50% of the rated current load.

● The hydraulic motor is equipped with a return oil pipe (internal leakage oil pipe); if the leakage amount is too large affecting normal operation (after two years), the motor parts need to be updated.

● The hydraulic motor spindle uses special imported sealing components with automatic wear compensation function; if external leakage is severe (after two years), the sealing components need to be replaced.

● The hydraulic motor is a precision machine; it is recommended to return to the factory for repair. Before returning, our company provides a spare motor for free use, which does not affect normal production.

Case display

-

File size: 1.4MB

-

File size: 725.7KB

Key words:

Suspended Hydraulic Drive Propeller